Outside of class, I work on many personal projects which also build on what I learn in class; for example, I constructed a dashboard-mounted phone mount for my car so that I could navigate without using my phone. I wanted the design to be integrated into the dashboard so that I did not damage the dashboard and it did not intrude on my vision of the road.

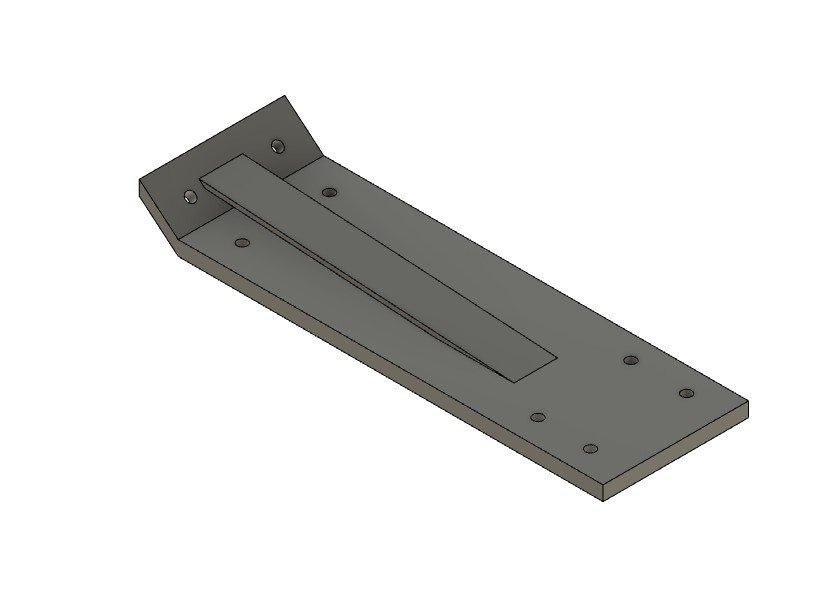

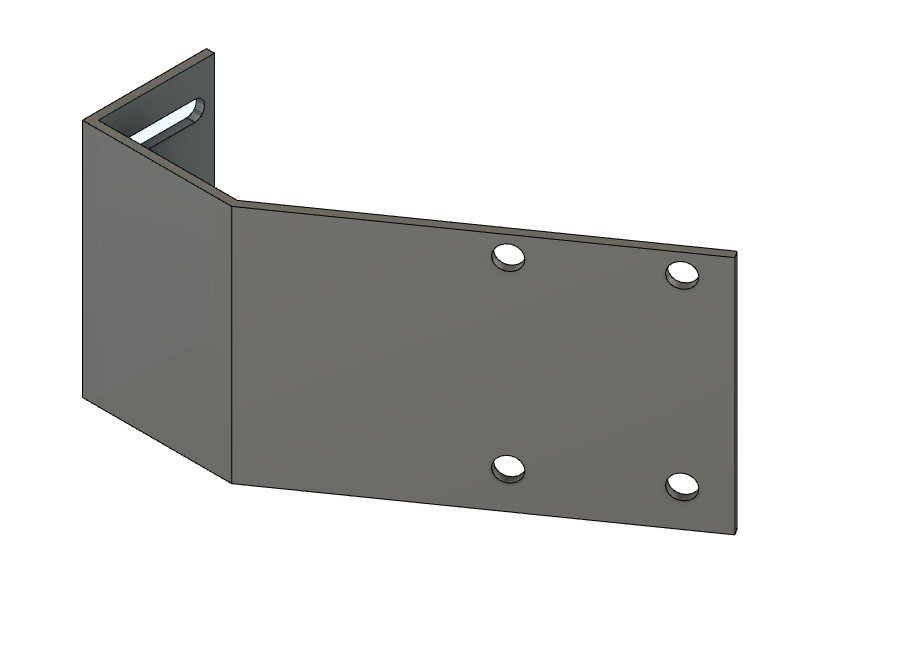

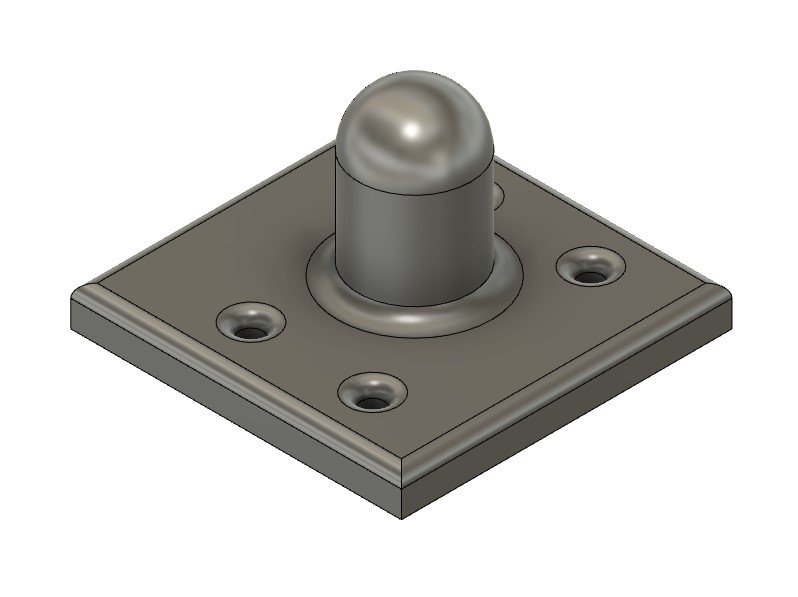

I decided to mount a sheet metal plate to the radio behind the dashboard and to bolt a 3d printed ball mount onto which I clamped an off-the-shelf phone clamp. Because of the implementation of the ball mounted clamp, the phone mount retained its freedom of rotation and catered to my needs perfectly.

Along the way, I encountered roadblocks and made revisions until I was completely satisfied with the end-product. Another advantage to the manufacturing processes used is that any part can be easily made again if it is damaged or another needs to be made.