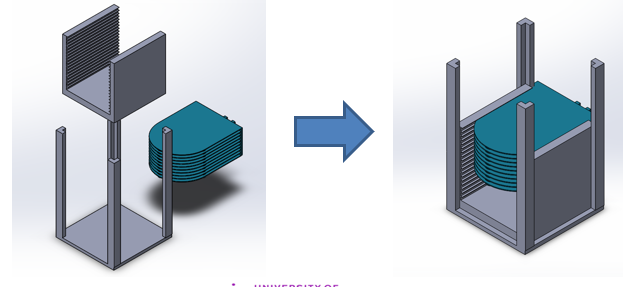

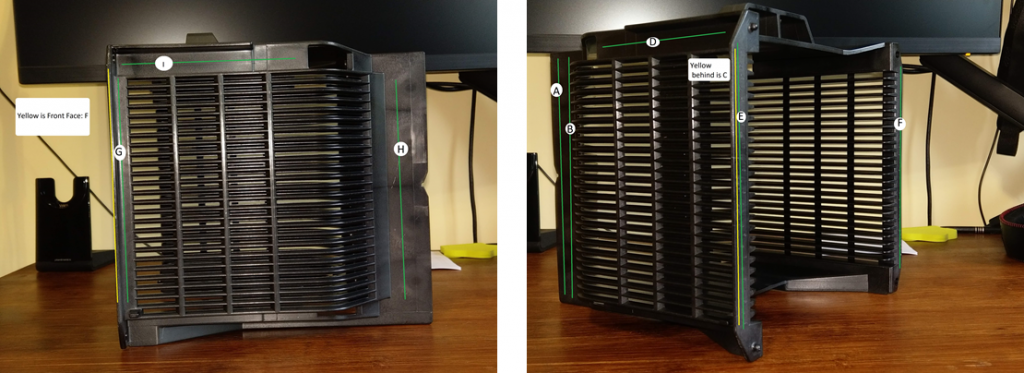

The University of St Thomas Senior Design program partners students up with companies in the Twin Cities to solve an engineering problem. My team partnered with Polar Semiconductors to create testing equipment to tolerance silicon wafer cassettes. In their production line, silicon wafer cassettes play an important role. The cassettes are used to transport the silicon wafers between machinery and for consistent access by the production equipment. Shown below is an example of the failure seen by Polar, the arm scrapes the bottom wafer instead of lifting the second wafer out.

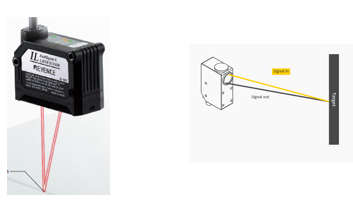

Having gone through multiple design iterations with different sensing types (shown below). We decided on sensing the dimensions of the cassettes with laser distance measuring sensors. A web of laser sensors identifies the dimensions of the important parts of the cassette, allowing us to give an accurate representation of the condition of the cassettes.

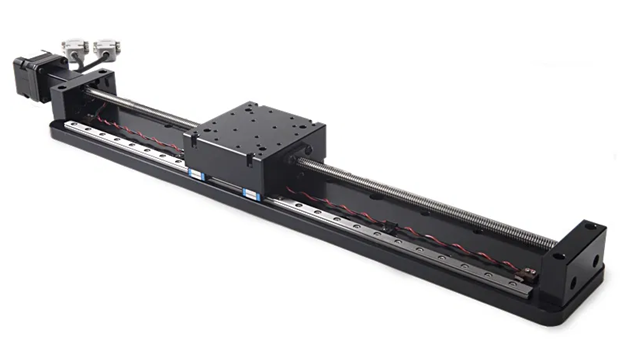

Now that we have decided on how we are going to take the necessary measurements, we needed to finalize the movement and frame design. To retain accuracy and speed, linear actuators were going to be used to move the laser sensors and the cassette to the correct measuring points. We decided that the LC Series Linear Stage from Newmark Systems (shown below) was the best option for our machine. This linear stage has incredible accuracy, high speeds, and can be easily programmed due to the use of NEMA 17 stepper motors.

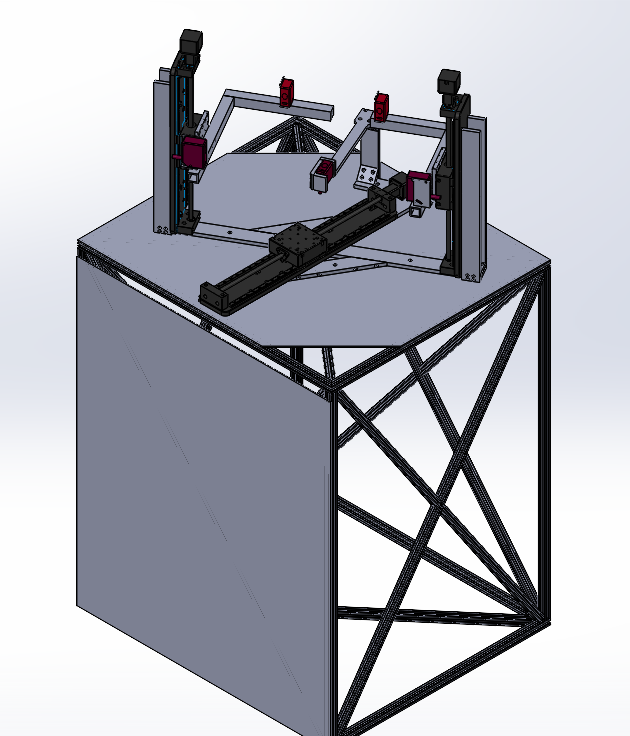

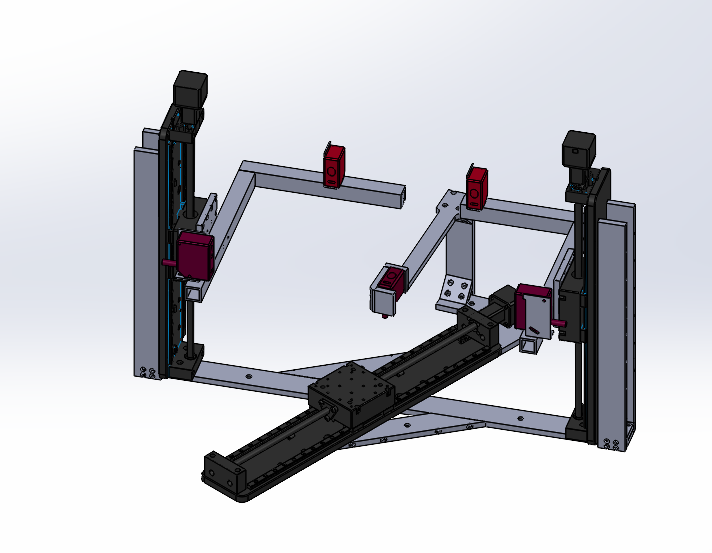

The frame was then designed based off of the necessary measurements needed on the cassettes and the geometries of the laser sensors and linear stages. The assembled frame is shown below. The frame was designed to be manufactured easily out of 3/8″ aluminum plate in machine shop by manual mills or CNC mills.

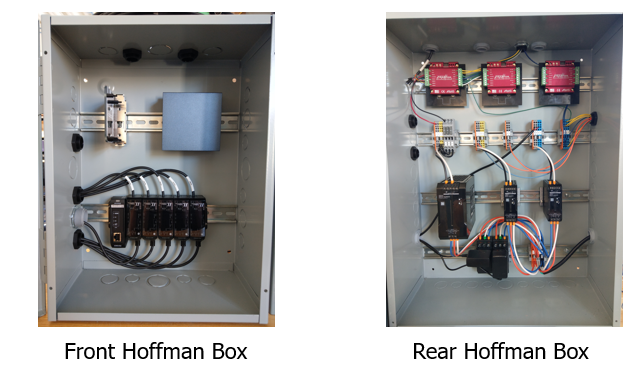

While the design was being finalized by myself, the electrical engineers began working on the electronics, wiring, and coding portions of the machine. We then collaborated on the design of the electrical housing box to create a safe and efficient setup and maintenance area (shown below). We also collaborated on the decision of wire gauge. Due to large amounts of power being drawn, heat was generated by the electronics. Completing a heat transfer analysis of the electronics, we were able to determine the best and safest wire gauge to wire the components with.

Due to shortages of materials, the physical materials of this project did not arrive until the end of the semester and the project was over. An assembly guide was completed to allow Polar Semiconductor to finish the assembly and the product could be completed easily by the technician onsite. This project presented many design challenges and roadblocks which had to be hurdled to complete this ambitious project. I learned so much about team management and communication through this project as well as challenging my technical skills more than any other project has. For more information about the project, the final report has been linked below for a more in-depth look at this ambitious project.